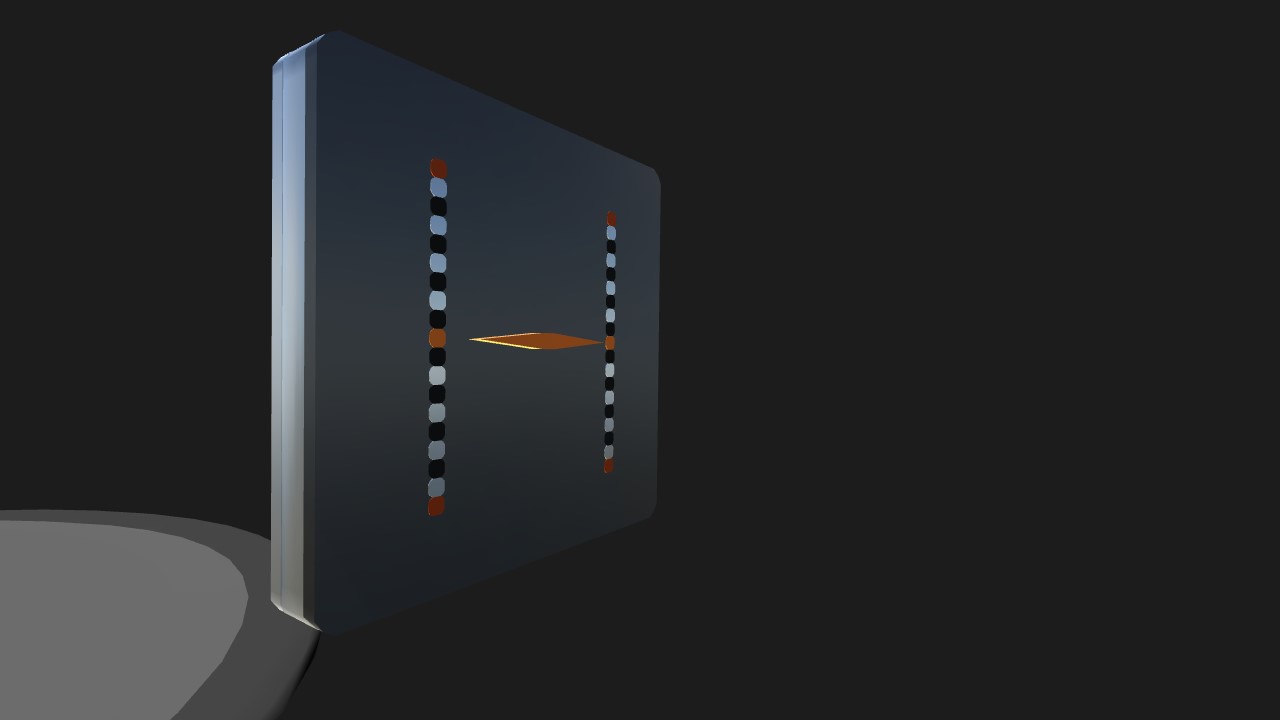

Proof of concept. For all of you cockpit builders out there, check this out.

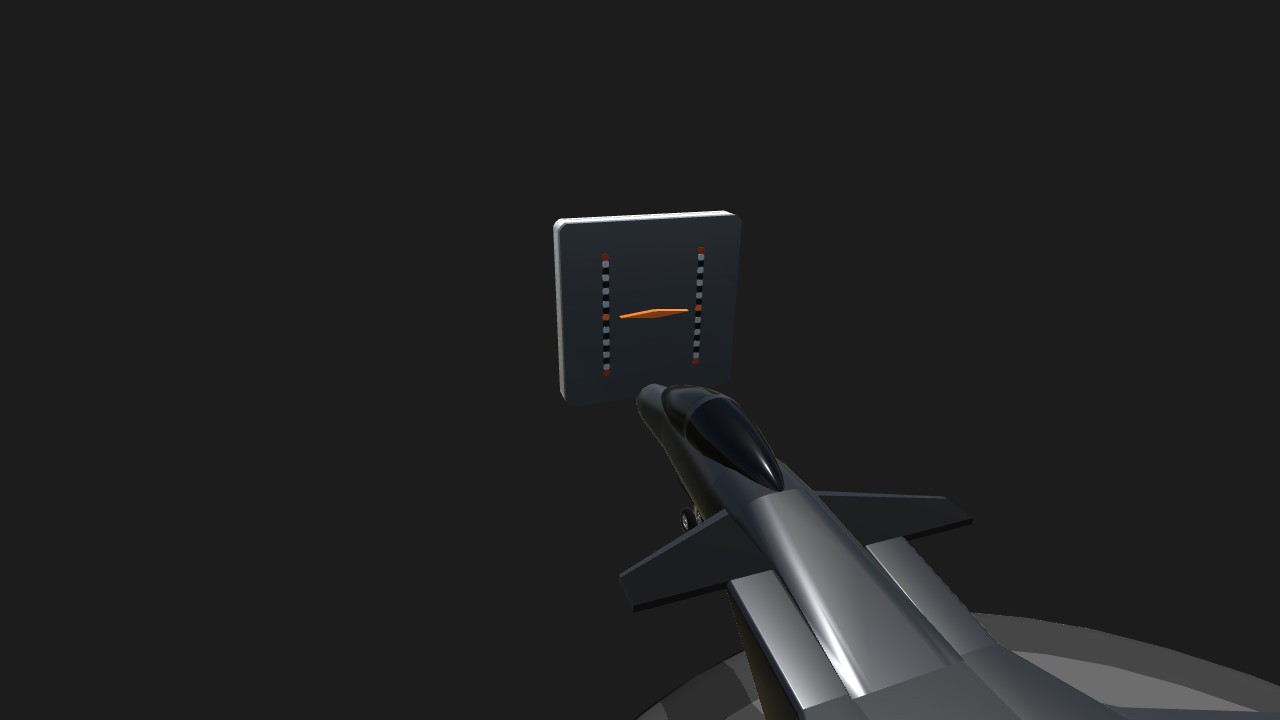

I have one attached to the nose of a jet so you can see the effects immediately (just press play, takeoff, pull some G's, and watch the needle move up and down).

In theory, it should be possible to do the math with turn radius and speed to calculate G-forces in-game, then adjust spring tension and dead-weight in the mechanism, to create an accurately scaled G-meter for a cockpit!

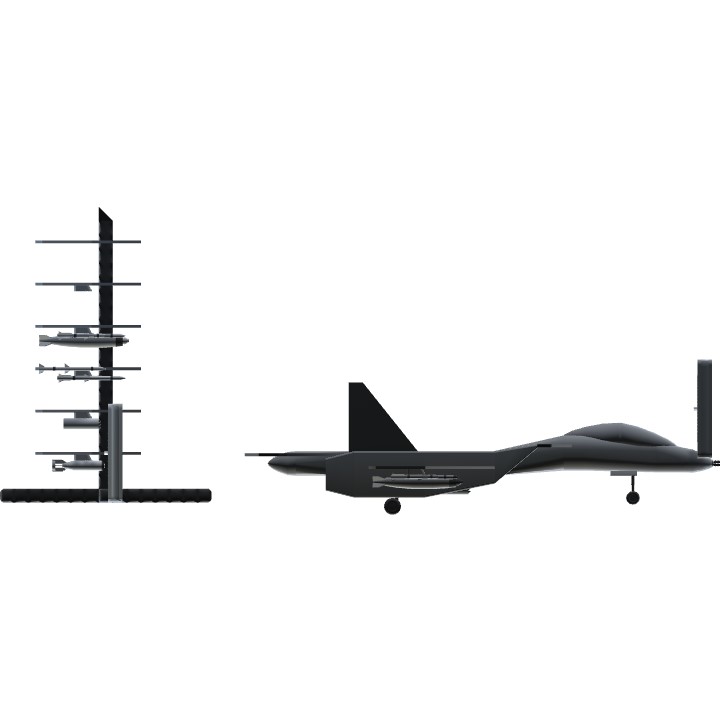

Theres an extra one behind the jet for you to easily save as a subassembly. I have left it scaled to the size I built it at for now (7x7) because I'm having some issues scaling it down and maintaining spring rigidity but I'm confident there's a solution.

Let me know what you think, and if this is something you guys would like to see worked on.

Specifications

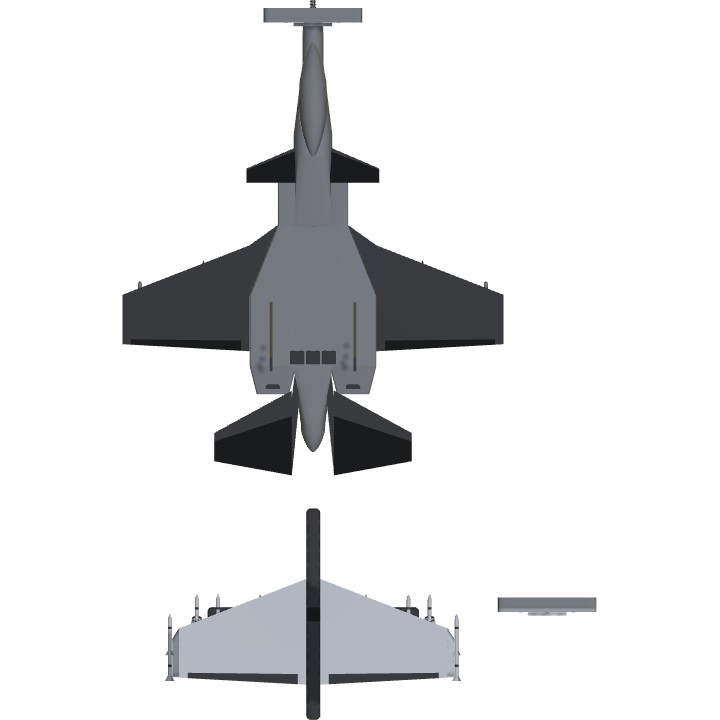

General Characteristics

- Predecessor (Ice Base Clearer) MS-07 Dominator

- Created On Windows

- Wingspan 55.0ft (16.8m)

- Length 83.7ft (25.5m)

- Height 35.7ft (10.9m)

- Empty Weight 24,130lbs (10,945kg)

- Loaded Weight 24,130lbs (10,945kg)

Performance

- Power/Weight Ratio 6.146

- Wing Loading 35.7lbs/ft2 (174.1kg/m2)

- Wing Area 676.8ft2 (62.9m2)

- Drag Points 17496

Parts

- Number of Parts 183

- Control Surfaces 6

- Performance Cost 1,999

G meter should be possible. It would have to be inverted if you do a free spin like I did. Take a look at my holo cockpit and study the holo part.

@Sauce Yes, I did. Before scaling it down, I added massScale="0" to every single part, then I removed the massScale="0" tag from the dead weight, and set the weight to some value. After that, I used Fine Tuner to scale the entire project down to something like 0.1 in size with "calculate mass" unchecked. The result was still a broken instrument (it was ok until it started moving).

When I have the time I'll mess with it - I think the solution is to decrease the dead weight in the mechanism since the spring strength is probably getting lowered with the down scale.

@AV8R rip just uncheck masscale when scaling XD

it tends to "break" the mechanisms when you masscale parts that you attach to rotators, pistons, shocks, etc.

Well it's simple but not so simple you made one @Sauce

@Sauce @CALVIN232 That's the down and dirty of it, yes. I stabilized it with a shock on the bottom, and a shock on either side with free-rotating hinges, so it doesn't move around with forward/backward acceleration.

If we can get it scaled down without it breaking things it would be a really cool instrument in a cockpit. The harder you pull, the more the needle moves. With some math we could get it to accurately display G-forces in-game.

@AV8R so it's a dead weight attached to a shock?

@Sarpentiu this could be useful for the cockpit

Very nice

@Gestour @Sauce @Rohan @Sarpanitu

Tagging you because you're experienced cockpit builders.