The McDonnell Douglas MD-80 is a series of five-abreast single-aisle airliners developed by McDonnell Douglas. It was produced by the developer company until August 1997 and then by Boeing Commercial Airplanes. The MD-80 was the second generation of the DC-9 family, originally designated as the DC-9-80 (DC-9 Series 80) and later stylized as the DC-9 Super 80 (short Super 80). Stretched, enlarged wing and powered by higher bypass Pratt & Whitney JT8D-200 engines, the aircraft program was launched in October 1977. The MD-80 made its first flight on October 18, 1979, and was certified on August 25, 1980. The first airliner was delivered to launch customer Swissair on September 13, 1980, which introduced it into service on October 10, 1980.

Keeping the fuselage cross-section, longer variants are stretched by 14 ft (4.3 m) from the DC-9-50 and have a 28% larger wing. The larger variants (MD-81/82/83/88) are 148 ft (45.1 m) long to seat 155 passengers in coach and, with varying weights, can cover up to 2,550 nmi (4,720 km). The later MD-88 has a modern cockpit with EFIS displays. The MD-87 is 17 ft (5.3 m) shorter for 130 passengers in economy and has a range up to 2,900 nmi (5,400 km).

The MD-80 series initially competed with the Boeing 737 Classic and then also with the Airbus A320ceo family. Its successor, introduced in 1995, the MD-90, was a further stretch powered by IAE V2500 high-bypass turbofans, while the shorter MD-95, later known as the Boeing 717, was powered by Rolls-Royce BR715 engines. Production ended in 1999 after 1,191 MD-80s were delivered, of which 116 aircraft remain in service as of August 2022.

Development

The DC-9 series, the first generation of the DC-9 family, entered service in late 1965 and became a commercial success with 976 units built when production ended in 1982.[2] The all-new designed aircraft family includes five members or variants (DC-9-10 / DC-9 Series 10, Series 20, Series 30, Series 40, and Series 50) with ten sub-variants or versions (Series 11, Series 12, Series 14, Series 15, Series 21, Series 31, Series 32, Series 33, Series 34, Series 41, and Series 51) and features two rear fuselage-mounted turbofan engines, a T-tail configuration,[3] a narrow-body fuselage with five-abreast seating for 80 to 135 passengers.[4] The success prompted the manufacturer to further develop the aircraft family with the last member, Series 50, as the reference aircraft.

Feasibility study

In the 1970s, McDonnell Douglas began development of the first derivative or second generation of the DC-9 family, a lengthened version of the Series 50, with a higher maximum take-off weight (MTOW), larger wing, new main landing gear, and higher fuel capacity. Availability of newer versions of the Pratt & Whitney JT8D turbofan engine with higher bypass ratios and thrust ratings drove early studies including designs known as Series 55, Series 50 (refanned Super Stretch), and Series 60. In August 1977, the design effort focused on the Series 55.

Program launch

With entry into service projected in 1980, the improved aircraft design was initially designated as the Series 80, which would be the sixth variant of the first generation.[5] In October 1977 Swissair became the launch customer for the Series 80 with an order for 15 plus an option for five.[3] The launch of the next aircraft models followed in October 1977 for the Series 81 (MD-81), on April 16, 1979, for the Series 82 (MD-82), on January 31, 1983, for the Series 83 ( MD-83). January 1985 for Series 87 (MD-87) and January 23, 1986, for Series 88 (MD-88).[6]

Certification

Type designation

Similar to the first generation of the DC-9 family, the second generation uses second-digit notation, with zero for variant names (Series 80) and non-zero for subvariant or version names (Series 81 through Series 88). Because there was only one variant within the second generation, the Series 80 became the family name and the Series 81 through Series 88 became variant or version names. The first Series 80, DC-9 line number 909, made its first flight on October 18, 1979, as the Super 80,[7] which then became the preferred designation for the newly developed aircraft family.[note 1] Although two aircraft were substantially damaged in accidents, flight testing was completed on August 25, 1980, when the first variant and respectively production model, the JT8D-209-powered Series 81, was certified under an amendment to the FAA type certificate for the DC-9. The flight-testing leading up to certification had involved three aircraft accumulating a total of 1,085 flying hours on 795 flights. After production of the first generation ended in late 1982, a new designation with McDonnell Douglas initials, MD-80, was proposed as the type designation for the second generation and in July 1983, McDonnell Douglas decided that the Super 80 would be officially designated the MD-80.[8] However, the type designation according to the type certificate (TC) is still the original (DC-9 prefix) to save on certification costs, but could also be provided with the new (MD prefix) written in parentheses, e.g. DC-9-81 (MD-81), DC-9-82 (MD-82), DC-9-83 (MD-83) and DC-9-87 (MD-87). Only the last variant, the MD-88, was officially certified under the MD designation.[9]

Type certification (TC)

An MD-81 of the type's launch operator, Swissair It was certified by FAA in August 1980

Following the MD-81's first flight on October 18, 1979, the MD-82 and MD-83 made their maiden flights on January 8, 1981, and December 17, 1984, respectively.[10] They were then certified by the FAA on August 25, 1980, July 29, 1981, and October 17, 1985, respectively. The first airliner, an MD-81, was delivered to launch operator Swissair on September 13, 1980.[11][6] Instead of merely using the MD- prefix as a marketing symbol, an application was made to again amend the type certificate to include the MD-81, MD-82, and MD-83. This change was dated March 10, 1986, and the type certificate declared that although the MD designator could be used in parentheses, it must be accompanied by the official designation, for example: DC-9-81 (MD-81). All Long Beach aircraft in the MD-80 series thereafter had MD-81, MD-82, or MD-83 stamped on the aircraft nameplate.[note 2]

An MD-87 operated by Scandinavian Airlines. The shortest variant, certified in October 1987

An MD-88 operated by Aviaco. The last and only variant certified with MD- prefix in December 1987[9]

The MD-87 and MD-88 made their first flight on December 4, 1986, and August 15, 1987, respectively.[10] Although not certified until October 21, 1987, McDonnell Douglas had already applied for models DC-9-87 and DC-9-87F on February 14, 1985. The third derivative was similarly officially designated DC-9-87 (MD-87), although no nameplates were stamped DC-9-87. For the MD-88, an application for a type certificate model amendment was made after the earlier changes, so there was not a DC-9-88, which was certified on December 8, 1987.[12] The FAA's online aircraft registry database shows the DC-9-88 and DC-9-80 designations in existence but unused.[13]

Type conversion (STC)

Type conversions were programs started in 2010 by third parties with support from the TC holder (Boeing, as this was only happening after the merger with McDonnell Douglas in 1997) to convert used MD-80 passenger airliners and provide the required supplemental type certificate (STC) from FAA or EASA.

AEI MD-80SF (freighter)

The MD-80SF was a freighter conversion program for the MD-80 series launched in February 2010, where the suffix SF stands for special freighter.[14] The conversion company, the Aeronautical Engineers Inc. (AEI) based in Miami, Florida, had noticed that pre-owned MD-80s could be bought for under $1 million, and at $2.5M for the freighter conversion, an MD-80FS could offer a narrowbody freighter for half the price of a Boeing 737-400SF.[15] The first conversion was undertaken on an ex-American Airlines MD-82 aircraft (FSN 49470 built in 1987), which was used as a test-bed for the supplemental type certificate.[16] The MD-80SF made its inaugural flight on 28 September 2012. AEI was the first and solely firm authorized by Boeing to receive the STC, ST02434LA, for the longer variants of the MD-80 series from the FAA in February 2013. [17] The converted freighter with the designation AEI MD-80SF would have a payload of 21.1 tonnes and the ability to take 12 pallets measuring 88 x 108 inches, which would be a good replacement for the Boeing 727 freighter[15] The first converted freighter, an AEI MD-82SF (the prototype), was delivered to the launch customer, Everts Air Cargo, in February 2013.[14]

In 2013, after the first delivery, AEI had orders for 20 MD-80SF freighters,[18] expecting more than 100 conversions over ten years. Despite the initial lively interest, the uptake had been sluggish.[15] AEI had six MD-80s converted by 2015, and three more were on the books for that year. Demand for the MD-80SF was disappointing due to two factors. First, the MD-80's cross section does not match the narrowbody freighter types used by the integrators, severely limiting the market for the freighter. Second, the values of the 737-400SF fell faster than expected, closing the gap with the MD-80SF, which burns 12 percent more fuel.[15] In October 2015, the MD-80SF was approved by the EASA with Doc. No. 10055029.[17] In 2021, after the COVID-19 pandemic, demand for cargo aircraft increased and the initial capital cost of an MD-80SF including conversion, paint and heavy maintenance was less than $5M, (~$5.35 million in 2022) half the cost of a 737-400SF, which made it attractive again. In March, USA Jet Airlines had signed a contract with AEI to convert three MD-88s into freighter, which they purchased from Delta Air Lines, and planned to have seven AEI MD-88SF in its fleet. AEI itself had delivered 21 AEI MD-80SF freighters, two were in progress and six had been ordered.[19]

EAT MD-87 (firefighter)

An EAT MD-87 for aerial firefighting was certified by FAA in 2014. Note the external ventral tank which adds a 4 ft "vertical safety distance" between the released retardant flow and the engines.

The FAA issued the Doc. No. STC ST02507LA, for Erickson Aero Tanker, LLC, located in Hillsboro, Oregon (referred to as "EAT") in 2014 to certify their EAT MD-87 firefighters.[20] In the said STC, EAT MD-87 air tankers are required to drop retardant with landing gear down to prevent stalling. The dedicated test pilot said that during a test with the external tank, the FAA representative was not satisfied with the aircraft's response after being placed deep in the stall (beyond the stall warnings, stick shaker, and stick pusher). In early 2017, EAT petitioned the FAA for an exemption from this requirement, 14 CFR 25.201(b)(1), and requested a "Flaps 40/Landing Gear Up" configuration while dropping, but on June 28, 2017, that exemption was denied with the reason given by the FAA that it would have allowed aerial firefighting retardant drops in a configuration that does not fully meet the stall characteristics requirements on the modified DC-9-87 (MD-87) aircraft. EAT was then working on an additional layer of status display to complement the existing system.[20][21]

Entry into service

The launch operator Swissair put the MD-81 into service on October 10, 1980, with a flight from Zurich to London Heathrow.[6] The MD-82, MD-83, MD-87, and MD-88 entered service later with Republic Airlines in August 1981, Alaska Airlines in February 1985, Austrian Airlines in November 1987, and Delta Air Lines in January 1988, respectively.[10][6]

Production

One of the final MD-80s built, an MD-83 for TWA, operating for American Airlines after the two companies merged

The second generation (later named MD-80s) was produced on a common line with the first generation DC-9s, with which it shares its line number sequence. After the delivery of 976 DC-9s and 108 MD-80s, McDonnell Douglas stopped DC-9 production. Hence, commencing with the 1,085th DC-9/MD-80 delivery, an MD-82 for VIASA in December 1982, only second generation or MD-80s were produced.

In 1985, McDonnell Douglas, after years of negotiating attributed to Gareth C.C. Chang,[22] president of a McDonnell Douglas subsidiary, signed an agreement for joint production of MD-80s and MD-90s in the People's Republic of China. The agreement was for 26 aircraft, of which 20 were eventually produced along with two MD-90 aircraft.[23] Upon cancellation of the co-production program, China refused to return the tooling used to McDonnell Douglas, and subsequently used it and the fuselage cross-section design in what became the Comac ARJ21 regional jet.[24]

During 1991, MD-80 production had reached a peak of 12 per month, having been running at approximately 10 per month since 1987 and was expected to continue at this rate in the near term (140 MD-80s were delivered in 1991). As a result of the decline in the air traffic and a slow market response to the MD-90, MD-80 production was reduced, and 84 aircraft were handed over in 1992. A further production rate cut resulted in 42 MD-80s delivered during 1993 (3.5 per month) and 22 aircraft were handed over.[11][page needed] MD-80 production ended in 1999, with the final MD-80, an MD-83 registered as N984TW, being delivered to TWA.[25]

Other proposals

MD-89

In 1984–1985, McDonnell Douglas proposed a 173-passenger, 152 in (390 cm; 12.7 ft; 3.9 m) stretch of the MD-80 called the MD-89, which would use the International Aero Engines V2500 engine instead of the regular JT8D-200 series engines.[26] The MD-89 was intended to have two 57 in (140 cm; 4.8 ft; 1.4 m) fuselage plugs forward of the wing and one 38 in (97 cm; 3.2 ft; 0.97 m) fuselage plug aft of the wing.[27] IAE and McDonnell Douglas announced an agreement to jointly market this 160 ft 6 in (48.9 m) derivative on February 1, 1985, but the concept was subsequently deprioritized in favor of the proposed MD-91 and MD-92 derivatives using ultra-high bypass (UHB) propfan engines. By 1989, however, lack of airline orders for the UHB derivatives caused McDonnell Douglas to return to the IAE V2500 engines to launch its MD-90 series aircraft.[3]

MD-80 Advanced

In order to better manage the transition from the second generation, MD-80, to the third generation, MD-90, McDonnell Douglas revealed at the end of 1990 that it would be developing an MD-80 "improvement package" with the intent to offer beginning in early 1991 for delivery from mid-1993. The aircraft concept became known as the MD-80 Advanced. The "main improvement" was the installation of Pratt & Whitney JT8D-290 engines (never built) with a 1.5 in larger diameter fan that would allow for a 6 dB reduction in exterior noise.[28] The MD-80 Advanced was to incorporate the advanced flight deck of the MD-88, including a choice of reference systems, with an inertial reference system as standard fitting and optional attitude-heading equipment. It was to be equipped with an electronic flight instrument system (EFIS), an optional second flight management system (FMS), and light-emitting diode (LED) dot-matrix electronic engine and system displays. A Honeywell wind-shear computer and provision for an optional traffic-alert and collision avoidance system (TCAS) were also to be included. A completely new passenger compartment design would have a 12% increase in overhead baggage space and stowage compartment lights that come on when the doors open, as well as new video system featuring drop-down LCD monitors above.[12] These changes would be also available by retrofit to existing MD-80s.[12] Due to lack of market interest, McDonnell Douglas dropped its plans to offer the MD-80 Advanced during 1991.[28]

In the course of 1993, a "mark 2" MD-80 Advanced version reappeared with the modified JT8D-290 engines as previously proposed.[12] In late 1993, Pratt & Whitney launched a modified version of the JT8D-200 series, the -218B, which was being offered for the DC-9X re-engining program, and was also evaluating the possibility of developing a new JT8D for possible retrofit on the MD-80. The 18,000 lbf (80 kN) to 19,000 lbf (85 kN) thrust -218B engine version shares a 98% commonality with the existing engine, with changes designed to reduce NOx, improve durability, and reduce noise levels by 3 dB. The 218B could be certified in early to mid-1996. The new engine, dubbed the "8000", was to feature a new fan of increased diameter (by 1.7 in), extended exhaust cone, a larger LP compressor, a new annular burner, and a new LP turbine and mixer. The initial thrust rating would be around 21,700 lbf (97 kN). A launch decision on the new engine was expected by mid-1994, but never occurred. The engine would also be available on new build MD-80s. McDonnell Douglas also evaluated the addition of winglets on the MD-80.[12]

Further developments

An MD-90 of Delta Air Lines, both its launch customer and last operator[29]

MD-90

The MD-90 was developed from the MD-80 series and is a 5-foot-longer (1.5 m), updated version of the MD-88 with a similar electronic flight instrument system (EFIS) (glass cockpit), and improved, and quieter IAE V2500 high-bypass turbofan engines. The MD-90 program began in 1989, first flew in 1993, and entered commercial service in 1995. The MD-90ER extended range version was also offered. Delta Air Lines flew the final MD-90 passenger flight on June 2, 2020, marking the retirement of the type.[29]

MD-95

The MD-95 was developed to replace early DC-9 models, which were approaching 30 years of age. The project completely overhauled the original DC-9 into a modern airliner. It is slightly longer than the DC-9-30 and is powered by new Rolls-Royce BR715 engines. The MD-95 was renamed "Boeing 717" after the McDonnell Douglas-Boeing merger in 1997.

Design

The MD-80 series is a mid-size, medium-range airliner, featuring a fuselage 14 ft 3 in (4.34 m) longer than the DC-9-50. The small, highly efficient wing design of the baseline aircraft was enlarged by adding sections at the wing root and tip for a 28% larger wing. The aircraft derivative retains the configuration of two rear fuselage-mounted turbofan engines, a T-tail, and has cockpit, avionics and aerodynamic upgrades. The airliner is designed for frequent, short-haul flights for up to 172 passengers depending on airplane version and seating arrangement.[30]

Flight deck

MD-83 Flight deck

The flight deck of the MD-80 aircraft was manufactured by Eaglesoft and Payne Aviation Software. It is equipped with a multi-panel electronic flight instrument system, a full flight management system, an air data computer, a traffic alert and collision avoidance system, a state-of-the-art inertial reference system, and LED dot-matrix displays for engine and system monitoring.[31]

Avionics

The MD-80 features an advanced avionics suite which includes two autonomous digital flight guidance computers. It is also equipped with a glareshield-mounted flight guidance control panel, flight director, autothrottle, thrust mode selection system, and an autoland system.[31]

Cabin

Five-abreast coach seating and four-abreast premium seating of the MD-80

The left side of the main cabin features aisle seats. It comprises three to six rows in the first class section, seven to 32 in the main cabin and around 21 in the exit row. It features five-abreast seating in the coach class.[31]

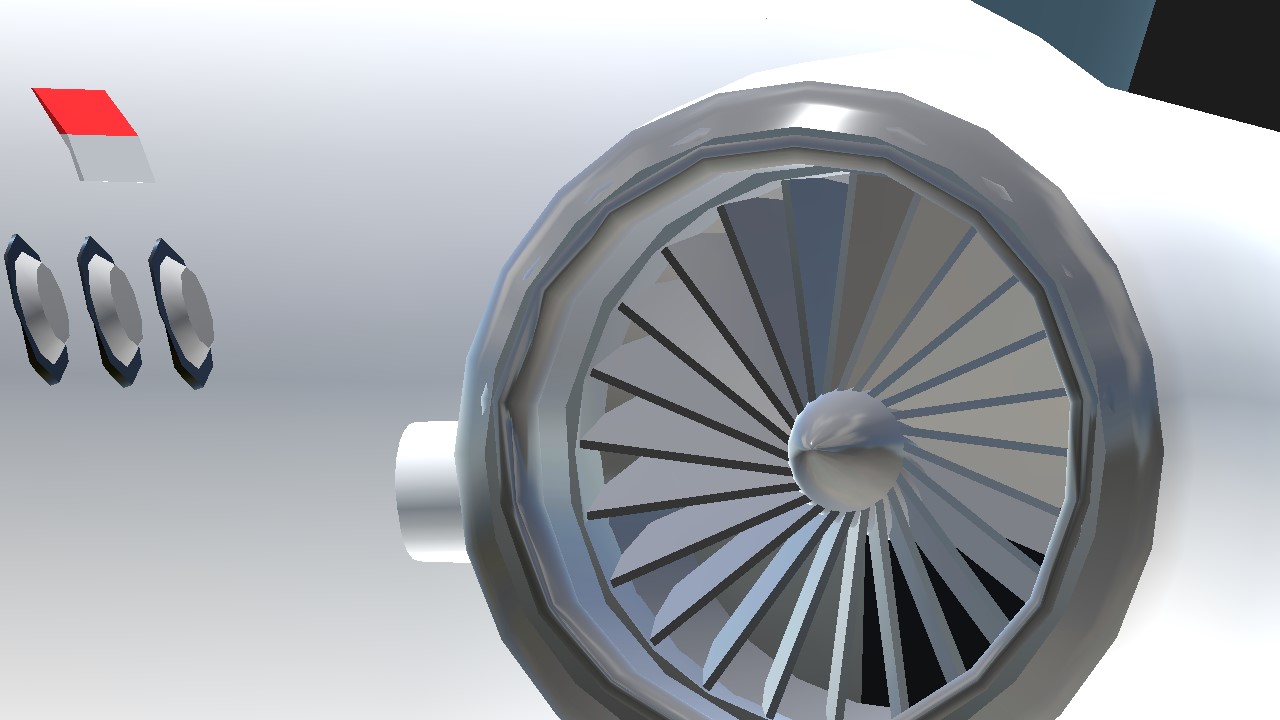

Engines

The MD-80 is powered by two more powerful, more efficient and quieter Pratt & Whitney JT8D-209 turbofan engines, which are a significant upgrade over the smaller JT8D-15, -17, -11, and -9 series. Each engine can produce 82–93kN of thrust. The JT8D-209 is an advanced engine operated by 350 operators to power around 4,500 aircraft. The engine provides high reliability and low maintenance costs. The engine operates at 77–84°F flat rated temperature.[clarification needed][31]

Performance

The maximum and cruise speed of the aircraft are 925km/h and 811km/h, respectively. It has a maximum range of 2,897km and a fuel capacity of 22,106l. The aircraft weighs around 35,300kg. The maximum take-off weight is 63,500kg.[31]

Operational history

Passenger

A Super 80 (MD-80) of American Airlines being deiced at Syracuse Hancock International Airport.

A Mad Dog (MD-88) of Delta Air Lines being serviced for a flight to Atlanta International Airport.

The second-generation, MD-80 series, passenger airliners have longer fuselages as well as longer range than their earlier counterparts, the first-generation of the DC-9 family. Some customers, such as American Airlines, still refer to the airplanes in fleet documentation as the Super 80, their former designation. Comparable airliners to the MD-80 series include the Boeing 737-400 and Airbus A319. It was the most delivered MD- series and often nicknamed as the Mad Dog[32] by the operators,[33][34][35] has been used by airlines around the world.[36][37] Major customers have included Aerolíneas Argentinas, Aeroméxico, Aeropostal Aerorepublica, Alaska Airlines, Alitalia, Allegiant Air, American Airlines, Aserca, Austral Líneas Aéreas, Austrian Airlines, Avianca, China Eastern Airlines, China Northern Airlines, Delta Air Lines, Finnair, Iberia, Insel Air, Japan Air System (JAS), Korean Air, Lion Air, Martinair Holland, Pacific Southwest Airlines (PSA), Reno Air, Scandinavian Airlines System (SAS), Spanair, Spirit Airlines, Swissair, Trans World Airlines and Meridiana.[38]

American Airlines was the first US major carrier to order the MD-80 when it leased twenty 142-seat aircraft from McDonnell Douglas in October 1982 to replace its Boeing 727-100s. It committed to 67 firm orders plus 100 options in March 1984, and in 2002 its fleet peaked at more than 360 aircraft, 30 % of the 1,191 produced. The MD-80 was the workhorse of the airline’s fleet throughout the 1980s and beyond.[39]

Due to the use of the aging JT8D engines, the MD-80 is not fuel efficient compared to the A320 or newer 737 models; it burns 1,050 US gal (4,000 L) of jet fuel per hour on a typical flight, while the larger Boeing 737-800 burns 850 US gal (3,200 L) per hour (19% reduction). In the 2000s many airlines began to retire the type. Alaska Airlines' tipping point in using the 737-800 was the $4 per gallon price of jet fuel the airline was paying by the summer of 2008; the airline stated that a typical Los Angeles-Seattle flight would cost $2,000 less, using a Boeing 737-800, than the same flight using an MD-80.[40]

In late March 2008 and again in early April 2008, an FAA safety audit of American Airlines forced the airline to ground all its MD-80 series aircraft (approximately 300) to inspect the wiring for one of the aircraft's hydraulic systems. This led to American canceling nearly 2,500 flights in March and over 3,200 in April. In addition, Delta Air Lines voluntarily inspected its own MD-80 fleet to ensure its 117 MD-80s were also operating within regulation. This resulted in Delta canceling 275 flights.[41][42]

Midwest Airlines announced on July 14, 2008, that it would retire all 12 of its MD-80s (used primarily on routes to the West Coast) by the fall.[43] The JT8D's comparatively lower maintenance costs due to simpler design help narrow the fuel cost gap.[44]

American Airlines announced that it would remove all of its MD-80s by 2019, replacing them with 737-800s.[45] The airline flew its final MD-80 revenue flights on September 3 and 4, 2019 before retiring its 26 remaining aircraft.[46] The final MD-80 flight on September 4, 2019, Flight 80, flew from Dallas/Fort Worth to Chicago–O'Hare.[47] The retired planes were flown later to the New Mexico desert to be mothballed.[39]

Delta Air Lines was expected to retire its MD-80 series jetliners at the end of 2020, but instead the airline began accelerating the fleet retirement in March 2020 when the COVID-19 pandemic saw passenger levels drop critically low for airlines. On June 2, 2020, the final flights arrived Delta's home base and hub Hartsfield-Jackson Atlanta International in Atlanta from Dulles International Airport in Washington, D.C., and George Bush International Airport in Houston.[48] This was the last scheduled passenger service in the US of any McDonnell Douglas airliner.[49] Delta's MD-80 fleet was put into storage.[50]

Freighter

An MD-82SF freighter of the conversion launch operator, USA Jet Airlines, at Tucson International Airport

In February 2013, Commercial Jet Inc. (CJI) delivered the first AEI MD-80SF, an MD-82SF (the prototype), to Everts Air Cargo, the launch customer of the MD-80SF passenger-to-freighter conversion program by the Aeronautical Engineers Inc. (AEI).[18] In August 2013, USA Jet Airlines became the launch operator of the MD-80SF freighter conversion program with an MD-88SF. The cargo airline purchased 15 MD-88 aircraft from Delta, six of which would be converted and the other nine used as spares.[51] USA Jet Airlines specialized in on demand cargo transport within North America.[19]

In 2021, most operators used the AEI MD-80SF freighter to carry Ford Motor Co. and General Motors automotive parts from Mexico to the U.S., but it was also used in Alaska for general freight and fish. The MD-80SF has a low deck height that allows it to load cargo from a pickup truck when needed, which is not possible on a Boeing 757 freighter. However, its cross section is too narrow to transport standard "A" type containers and instead a dozen non-standard 88 x 108 inch containers or pallets, which is the main disadvantage in cargo operations.[19]

In late July 2022, Everts Air Cargo (EAC) selected Universal Avionics, an Elbit Systems company, to deliver cockpit upgrades (avionics, FMS with LPV capability, and integrated GPS) for its MD-80SF aircraft to improve safety and operational efficiency. EAC specializes in transporting freight and mail in Alaska and uses its MD-80SF fleet to supply on demand charter service operations throughout the United States, Canada, Mexico, and Caribbean Islands.[52]

Firefighter

An EAT MD-87 air tanker with landing gear down during the retardant drop onto the Boxcar Fire in Central Oregon in June 2018.

As of July 2022, Erickson Aero Tanker operates six MD-87 aircraft converted for use as aerial firefighting air tankers for the U.S. Forest Service, California Department of Forestry and Fire Protection and other government agencies.[53][54] The MD-87 air tanker's capacity is 4,000 gallons or 1,920 gallons more than the capacity of the Lockheed P-2 Neptune tankers and 1,000 gallons more than Bae-146 tankers. That is well short of the 19,000+ gallon capacity of the 747 Global Super Tanker, but the MD-87 is much more cost-effective to operate and can utilize more austere fields with shorter runways.[55] The MD-87 firefighter is loaded using one or two (individual or simultaneously) 3-inch coupled loading ports on each side of the fuselage. These ports can sustain up to 600 gallons per minute flow maximum. Few, if any tanker bases utilize both ports, loading using a single port at an average flow rate of 450 gallons per minute, giving the load time of under seven minutes.[53]

Another interesting feature of the MD-87 tanker, as well as Douglas DC-7s and some other large tanker-modified aircraft, is that the plane can be flown with the landing gear down during the retardant drop, which reduces airspeed while allowing higher engine RPMs, reducing lag on post-drop climb out- similar to a speed break. Occasionally only the main gear are extended with nose gear stowed. When pulling off or up after a retardant drop the pilots simply want as much aircraft performance available as possible.[55]

Variants

This section includes a list of general references, but it lacks sufficient corresponding inline citations. Please help to improve this section by introducing more precise citations. (July 2015) (Learn how and when to remove this template message)

Douglas MD-80 Family, top to bottom: MD-81/82, MD-83/88, MD-87, MD-90

References: Flight International's Commercial Aircraft of the World 1981,[56] 1982,[57] 1983,[58] Jane's All the World's Aircraft 1994–1995,[59] and 2004–2005.[60]

Dimensions

The basic "long-body" MD-80 versions (MD-81, MD-82, MD-83, and MD-88) have an overall length of 147 ft 10 in (45.06 m), and a fuselage length of 136 feet 5 inches (41.58 m) that is 4.62 m longer than the DC-9-50 and 13.5 m longer than the initial DC-9, the Series 10. Wingspan was also increased by 4.4 m in comparison with earlier DC-9s at 107 feet 10.2 inches (32.873 m). The aircraft's passenger cabin, from cockpit door to aft bulkhead, is 101 feet 0 inches (30.78 m) long and, as with all versions of the DC-9, has a maximum cabin width (trim-to-trim) of 123.7 inches (3.14 m).[citation needed]

Powerplant

The initial production version of the MD-80 was the Pratt and Whitney JT8D-209 18,500 lbf (82 kN) thrust-powered MD-81. Later build MD-81s have been delivered with more powerful JT8D-217 and -219 engines.

APU

All versions of the MD-80 are equipped with an AlliedSignal (Garrett) GTCP85-98D APU as standard, which is located in the aft fuselage.

Flight deck

The MD-80 is equipped with a two crew flightdeck similar to that on the DC-9 from which it evolved. Later models could be equipped to a higher specification with EFIS displays in place of the traditional analogue instruments, TCAS, windshear detection, etc. An EFIS retrofit to non-EFIS-equipped aircraft is possible.

Cabin

Typical passenger-cabin seating arrangements include:[11][page needed]

A mixed-class, with aft full-service galley, configuration for a total of 135 passengers with 12 first class, four-abreast 36-inch seat pitch.

123 economy-class passengers, five-abreast, 32-inch pitch.

All-economy layout for 155 passengers, five-abreast, 32- and 33-inch pitch.

A typical high-density layout is for 167 in one class (i.e., Airtours).

Undercarriage

All versions of the MD-80 are equipped with a tricycle undercarriage, featuring a twin nose unit with spray deflector and twin main units with rock deflectors. The MD-80T, developed for the Chinese, differs in that the main units are each fitted with a four-wheel double-main-bogey undercarriage to reduce pavement loading.[11][page needed][58]

Aerodynamic improvements

From mid-1987, new MD-87-style low-drag "beaver" tail cones were introduced on all series of MD-80s, reducing drag and improving fuel burn. Some operators have been modifying the old DC-9-style cones on earlier-build MD-80s to the new low-drag style. Scandinavian Airlines System has done this, citing the improved economics and cosmetics from the modification.[11][page needed]

MD-81

Scandinavian Airlines MD-81 taking off

The MD-81 (originally known as the DC-9 Super 81 or DC-9-81) was the first production model of the MD-80, and apart from the MD-87, the differences between the various long-body MD-80 variants are relatively minor. The four long-body models (MD-81, MD-82, MD-83, and MD-88) only differ from each other in having different engine variants, fuel capacities, and weights. The MD-88 and later-build versions of the other models have more up-to-date flight decks featuring for example EFIS.

Performance

Standard maximum take-off weight (MTOW) on the MD-81 is 140,000 lb (63,500 kg) with the option to increase to 142,000 lb (64,400 kg). Fuel capacity is 5,840 US gallons (22,100 L), and typical range, with 155 passengers is 1,565 nmi (2,898 km).[11][page needed]

MD-81 timeline

Formal launch: October 1977

First flight: October 18, 1979

FAA certification: August 25, 1980

First delivery: September 13, 1980, to Swissair

Entry into service: October 10, 1980, with Swissair on a flight from Zurich to Heathrow.

Last delivery: June 24, 1994, to JAL Domestic

Specifications

General Characteristics

- Predecessor XJ-90

- Created On Android

- Wingspan 95.8ft (29.2m)

- Length 156.1ft (47.6m)

- Height 31.8ft (9.7m)

- Empty Weight N/A

- Loaded Weight 42,583lbs (19,315kg)

Performance

- Power/Weight Ratio 1.345

- Wing Loading 28.9lbs/ft2 (141.1kg/m2)

- Wing Area 1,474.0ft2 (136.9m2)

- Drag Points 10302

Parts

- Number of Parts 298

- Control Surfaces 5

- Performance Cost 1,704

K

Y'all can make a livery bruh