Update 1.1: Fixed flaps

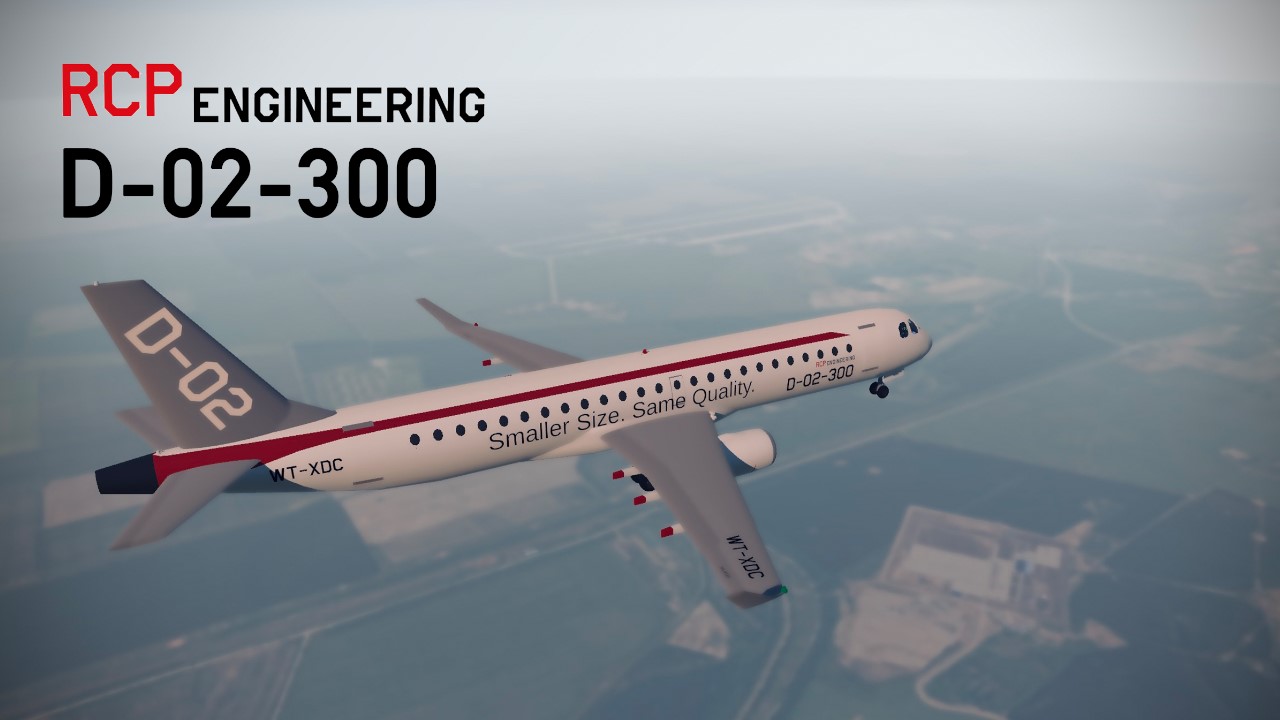

House Livery

The TAP Express livery has a lot of text labels, so if you're afraid of lag, feel free to download this alternate livery.

Notes

This is for WinsWings's Regional Airliner Challenge, which, as you can see, I'm 13 hours late for, because I had irl stuff going on. Hopefully, it'll still be accepted.

The livery here may seem underwhelming, since it's made out of text labels. However, I spent about 1 hour just to Photoshop the tail logos to remove all the watermarks. Furthermore, the tail logos for the left and right sides are completely different, so it took me a while to find accurate ones.

I also spent countless hours tweaking all the mechanical items on this aircraft, so don't be mistaken that this is just my D-01 copied and pasted over; this is really a clean-sheet design.

Also, this plane was partially based off the Embraer E190, so it looks quite similar.

I hope you'll leave an upvote or spotlight on the D-02, and as always, enjoy my long, long lore!

About the D-02

Source: Wikipedia

The RCP Engineering D-02 is a series of short-haul regional airliners built to compete with the Bombardier CRJ series and Embraer E-Jet family.

History

Riding on the success of the D-01 family, RCP Engineering's Airliner Manufacturing division hired new workers, and opened a new assembly line at Martin South Airport.

But most notably, RCPe decided to expand into the regional sector, beginning work on a new advanced regional airliner that would replace aircraft like the DC-9 and Boeing 717.

By 2001, preliminary design work was completed, and the D-02 was announced at the 2001 Paris Air Show. Major airlines like Air France, Japan Airlines's J-Air and British Airways placed firm orders on the aircraft.

On 7 March 2003, the first functional D-02 prototype, registered WT-XDC, made its first flight from Martin South Airport. In total, 3 prototypes were built, and they flew at the Farnborough and Paris Airshows.

The first production-model D-02, a -300, was delivered to Air France in 2005. The -200 (smallest model) made its first commercial flight 7 months later, and the -400 (largest model) did so in 2006.

Design: High-Wing VS Low-Wing

The original design submitted by the RCPe engineers was a high-wing, T-tail aircraft, similar to the BAe 146/RJ100.

A sketch of the original D-02 concept.

Although a high-wing design allowed for better performance and lower landing speeds, the RCPe supervisors rejected the proposal as:

- the engines would be harder to maintain,

- as the engines are located right next to the fuselage, the amount of cabin noise would be astronomical,

- a high-wing design would prevent the fuselage from being stretched,

- and finally, the D-02 would cater to US and European airlines which already had access to well-developed airports, so performance on uneven terrain was a low priority.

In the end, the engineers went back to the drawing board and came up with a low-wing design, which is what you see today.

I'm not kidding; I actually changed the entire plane's design abruptly after considering these.

Flying with TAP Express

Yes, TAP is a real airline (it's literally Portugal's flag-carrier), and TAP Express operates E190s in real life. However, in my fictional universe, instead of E190s, the airline chose to fly D-02-300s.

Note that the E-Jet family coexists with the D-02 family, it's just that some airlines flew D-02s, while others still chose to fly E170s and E190s.

The registration is real, and it belonged to an E145 operated by Portugália Airlines, the predecessor to TAP Express.

Feel free to make liveries on my plane, but please tag me on them!

Full List of My Builds (click on this)

Specifications

General Characteristics

- Predecessor Regional Airliner CHALLENGE (CLOSED)

- Successors 2 airplane(s) +370 bonus

- Created On Mac

- Wingspan 93.9ft (28.6m)

- Length 115.4ft (35.2m)

- Height 36.7ft (11.2m)

- Empty Weight N/A

- Loaded Weight 49,712lbs (22,549kg)

Performance

- Power/Weight Ratio 1.763

- Wing Loading 45.0lbs/ft2 (219.6kg/m2)

- Wing Area 1,105.3ft2 (102.7m2)

- Drag Points 22986

Parts

- Number of Parts 556

- Control Surfaces 9

- Performance Cost 2,179

Nice work. Nice drawings too. Good luck for the challenge.

Nice plane! Can I make a livery for my fictional country?

Nice work 👍

RIP Flybe

@AlivePan because I gave him permission to do this, while the guy who posted the 737 probably didn’t, or you didn’t ask him.

Although if you did ask the OP before posting, yeah it’s either because of your rank, or because the mod team doesn’t want to start another drama involving CoachPickles86.

Hey man. Just wanted to ask you about the challenge that CoachPickles86 is having. So basically, I did a similar challenge like this when I had around 500-700 points but with a 737-900 and it got removed. How come this isnt removed yet? I also gave credits back then. Is it because he has more points?

They told me to "Build my own 737" but here I am building 2 planes at once. Shouldnt pickles also build his own airliner? Man im more disappointed than ever.

@YoboyTrimix 😱😱😱😱😱😱😱

@RepublicOfCursedPlanes I almost got rick rolled but my YouTube has it we’re when I open a link it’s auto paused so nice try

Wow, somehow i completely missed this. Was waiting for a while to try this one out.

I always try to download planes but it doesn't work wth

not cursed

@RepublicOfCursedPlanes ok

@CoachPickles86 also, tag me on the challenge when you make it

@RepublicOfCursedPlanes ok

@spacegenius747 🤫

@RepublicOfCursedPlanes

No, for I know it is a rickroll

@spacegenius747 there’s nothing wrong with the link, it just redirects you to the Wikipedia homepage. Trust me!

DONT CLICK WIKIPEDIA.

YOU HAVE BEEN WARNED

@FeiGe3 LETS GOOOOO

@CoachPickles86 hmm… do it if you want, but remember to credit me and make sure that all entries are a successor to this plane.

@RepublicOfCursedPlanes Can i make the challenge about D-02 plane livery

@RepublicOfCursedPlanes After testing, flap will not fall.

@FeiGe3 alright, I've updated the plane, do the flaps still fall off?

this look like a embraer plane -_-

( ͡• ͜ʖ ͡•)